“DURESCO on your Walls will bring DIGNITY, FRESHNESS and BEAUTY to your Home”.

At the very beginning of the twentieth century it was announced that:

The Guildhall, London was regularly treated with Duresco

The Foreign Department Buildings, Oslo was recently decorated outside with Duresco

The Bank of Brussels, The Old Palace of Flanders was recently decorated inside with Duresco

The Gleneagles Hotel had been treated INSIDE and OUTSIDE with Duresco

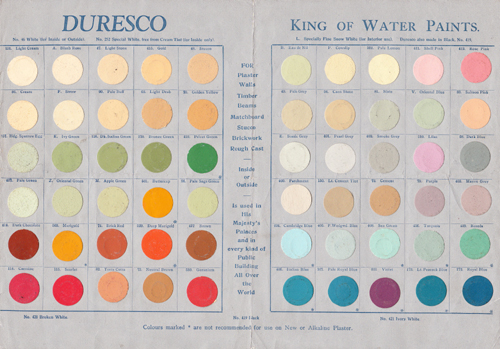

All this aside, it seems as though Duresco had good reason to call itself “The King of Water Paints”.

The shortcomings of the conventional size-bound distempers have been raised in another post entitled The Problem with Distemper. Apart from their fragility, the…

The rest of this essay has been removed after six years. You can now read more about this in The Anatomy of Colour, published by Thames & Hudson and available from John Sandoe (Books).

View Larger Map

Family folklore has it that Duresco and the name Jukes were closely connected. The Jukes side of my family broke away shortly after WW2. Do you have any information that I might find interesting?

Sorry to bother you but I would be immensely interested.

Many thanks,

Tony Jukes.

Thank you for your enquiry.

I’m sorry for my delayed response, but your email reached me on holiday and I wanted to check the facts before replying.

I have had a look through the text and group photographs in “Orr’s Zinc White 1898-1948″ but cannot see any reference to the name Jukes. There is very little that I have found written on ‘Duresco’, but I shall keep an eye open.

Best wishes

Patrick Baty

Dear Tony,

I have just read your message to Patrick Baty on the subject of Duresco paints. My mother was Mary Adeltrude (Pearl) Elphick née Jukes and her grandfather was Francis Ignatius Jukes. My father, Steve Elphick, was employed by Duresco before and during the war years. I am compliling a family tree and would like any info. you may have regarding any of the above. In return I am happy to offer any information or answer any questions that I can.

Best wishes,

Julian Elphick

I am a great-grandson of Francis Jukes who I can confirm was a partner of Mr J B Orr in the Silicate Paint Company in Greenwich. I can send a copy of the Jukes Family Tree to Mr A J Jukes if he wants it.

regards

Bob Phillips

Bob

I’d love a copy of the Jukes family tree you have

I am Tony Jukes’ Niece and live in Sydney, Australia where my Father Michael Jukes came with his new wife, Elizabeth, in 1960 as £10 Poms…

Please can you email me?

Thank you!

Susan

Hello Susan Jukes. Please contact me on email address bertiepenguin@virginmedia.com and I’ll see if I can get you a family tree copy.

regards

Bob

Susan,

Please forgive me contacting you but I came on comments when looking at the “Duresco King of paints article.

The discussion stream asked the question I had been considering about the connection of my grandfather Francis Ignatius Jukes of Brighton and Eltham who was said, in the family, to have “invented emulsion paint”!! obviously this is fantasy but he was listed as a director in 1914, while living in Eltham.

I would be very grateful and interested in anything you might be able to say about this.

I am also constructing a family tree and wonder how these threads fit together.

Many thanks

Steve

Steve,

I cannot help you with the genealogical aspects, but I can comment on the paint issues. Yes, it is true, in a fashion, that your grandfather did invent emulsion paint. ‘Duresco’ was the best-known of the early oil-in-water paints and as such a true emulsion. You can see more on this here http://patrickbaty.co.uk/2009/05/10/the-problem-with-distemper/

Hallo Patrick my late grandfather was a colourmatcher at Duresco for 62 years and my late father was a mechanic/driver for them between 1940-1953 the factory was as you probably know in Charlton where the Thames Barrier is situated now. I would think they were still producing into the late sixties early 70′s .The owner who my grandfather always talked about was Phil Jukes who I believed had a brother Austin Jukes who I do not think had any input in the buisness , I think Austin was still alive in the 1990′s. I actualy have a multi-layered clock crafted from a large layer of paint removed from a wall at Duresco where over the years my grandfather had scraped his pallette knife! Feel free to email me for any more info .

Richard, that’s absolutely wonderful. It’s things like this that makes the past come alive. If you wanted, and were able, to take a photo of the clock, I’d love to include it. That really is unique.

Will photograph clock & will try to upload in the next couple of days

Richard.

Thanks. That would be great. You may have seen that a couple of Jukes relations have been in touch. They may be able to supply more detail.

Dear Patrick,

I found an old photograph of a sign advertising Duresco protecting old books of gold leaf. On the back was a hand written note “The King of….” as though it was an instruction perhaps for the sign to be altered. I have posted it on my pinterest page under https://www.pinterest.co.uk/pin/541276448969731772/

Might possibly have come to me via the Keep’s Paints family.

Best Regards,

Simon Thrower

Thanks Simon. Very interesting. We dealt with Keeps for very many years.