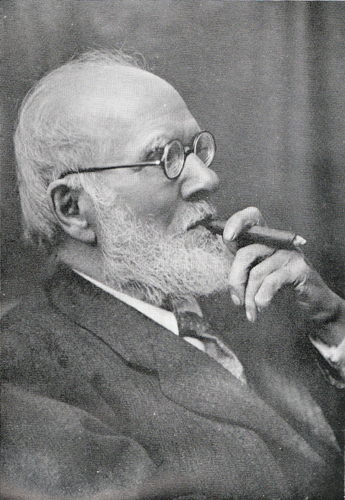

Inventor of Orr’s Zinc White

John Bryson Orr had devoted himself to the search for a satisfactory white pigment and a sound practical method of producing it commercially.

Nearing ninety years of age, he said:

“Little did I think when I began experimenting, about 1860-1861, with a view to producing a new white pigment that I should see that pigment grow to such importance as to create a new industry with its present day output of over a quarter million tons annually.”

For it was at that time that he carried out experiments on mixed zinc and barium pigment and seven years later produced the pigment in bulk. In 1872 he set up a factory in Glasgow for the manufacture of Lithopone. While the Frenchman G.F. de Douhet must be considered the pioneer of the lithopone industry, it was Orr who perfected the technique and developed a viable method of production. In 1874 he patented the process for making Orr’s Zinc White.1

The rest of this essay has been removed after five years. You can now read more about this in The Anatomy of Colour, published by Thames & Hudson and available from John Sandoe (Books).

View Larger Map

Fascinating stuff.

Thank you, Adrian.

My sister brought this to my attention; found it interesting as we were brought up on a street next door to the Widnes Works. There was a huge tip of waste product opposite our house, which only ever grew higher. We left there about 1954 but can’t remember when the factory closed. The local market and a Morrison’s supermarket are now on the site.