A previous post has already introduced the subject of a most useful work that was published in the 1930s – Parsons’ Decorative Finishes. Subsequently I have used it as a ‘prompt’ for posts dealing with Imitation Stone Paints, Permanent Greens, Gloss Enamel Finishes and Gloss Finishes.

The book is divided into 17 sections and it is the first three of these that will be considered in this post, which looks at a semi-gloss finish offered by Thomas Parsons’ at the time. Some of the other finishes were classed as enamels and these have been discussed in an earlier post. Others, called hard-gloss finishes, were covered in another post.

Section One

The first section of Parsons’ Decorative Finishes is headed Bill of Quantities and gives the framework for anyone wishing to specify the paints contained in the book.

Section Two

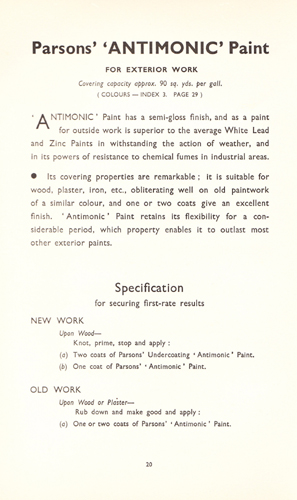

Explains where each of the Parsons’ finishes was best used and provides a Specification for New and Old Work.

Parsons’ ‘Antimonic’ Paint was a semi-gloss paint designed for exterior use. It was considered more weather-resistant than either White Lead or Zinc paints and less susceptible to chemical fumes in industrial areas. The name ‘Antimonic’ comes from the main ingredient – Antimony Oxide.

Such is the deep conservatism of the painting and decorating trade that it comes as no surprise to see that Antimony Oxide, which was put on the market (under the proprietary name Timonox) in 1919, was being suggested as a pigment over fifty years before:

In a paper lately read before the Academy of Sciences in Paris, it is stated that the flowers of antimony yield a finer white (than Ceruse), mix more freely with the other colors, are more durable, and cost only one-third of the price of white lead; while, neither in the process of manufacture, nor in use, does this substance affect the health of the workmen.

Antimony oxide is a fume pigment produced by roasting the native ore stibnite until it volatilises, the smoke or fume being carried into condensing chambers where it cools and condenses into a soft white powder. It is of very fine texture and the best grade is a very pure white of good opacity. It has a very slight retarding effect on the drying of linseed oil and yields a rather soft film, but when combined with about 10 per cent zinc oxide it is much improved and was said to afford good protection against sea air.

The following formula, given by the manufacturers of Timonox gives an idea as to the general composition of paints from antimony:-

| Timonox | 612.50 |

| Zinc oxide | 87.50 |

| Barium sulphate | 175.00 |

| Refined linseed oil | 125.00 |

| 1000.00 |

1930s Paint Colours

Should anyone want to use any of the paint colours shown on these colour cards Papers and Paints will be able to match them in most conventional finishes.

View Larger Map

No comments yet. Be the first!