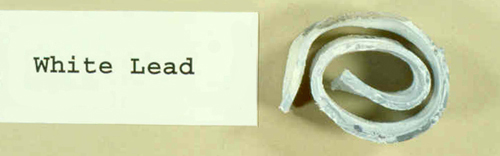

White lead, or lead carbonate,1 is the pigment that formed the basis of most oil paints used in the decoration of houses until comparatively recently. When combined with linseed oil it forms a lead soap2 which gives it excellent working properties – drying and covering well it produces a slightly elastic film which enables it to expand and contract with changes in the temperature in unison with the surface to which it has been applied. The main drawback, however, is its toxicity.

The rest of this essay has been removed after five years. You can read more about the subject in The Anatomy of Colour, published by Thames & Hudson and available from John Sandoe (Books).

View Larger Map

It’s not that the site works better with cookies, it’s that I can’t access it without them, because if click ‘Decline’ it sends to that other, weird looking site (I thought it might be a one-time thing, but no) and I instantly get my guard up.

That said, I enjoyed the article.

Poor people… and animals.

Yes, I am aware of that. However as part of the recent legislation website owners are required to display the fact that they are using cookies to website visitors.

As I am using Google Analytics and a variety of other authenticated plugins the site needs users to agree to this or otherwise they cannot view the site.

Apparently it only appears as a one time pop-up for new visitors.

Sorry about the inconvenience, however I’m just trying to follow these new regulations.

I’m glad that you enjoyed the article, nonetheless.

Fascinating article. Thank you for sharing!

Dear Patrick, I very much enjoyed your article particularly the pictures of the lady workers, gone are the days where women did a proper days work (just joking).

I just thought I would like to share with you I have completed my first stack with very interesting results. It jolly well works! We have as a result aquired half a ton of lead for the further development of the white as a tube colour.

Best Wishes

Michael

That’s amazing. Yes, I’m delighted that a source of proper Flake White is available for artists although, as you will see, I’m less convinced about its continued use in buildings.